CARD CLOTHING

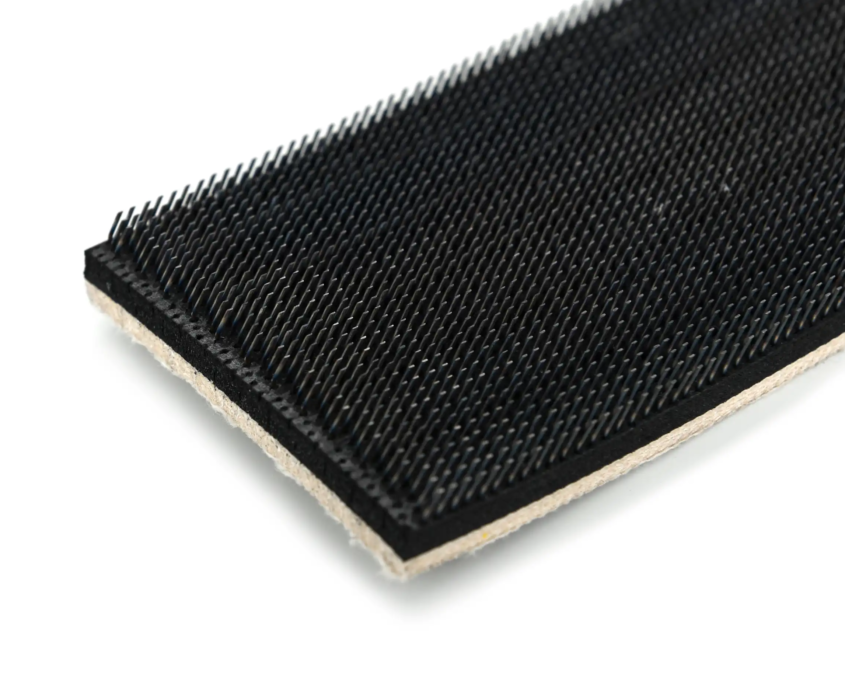

UB-Tec specializes in the production of flexible card clothing designed for woolen and worsted carding machines. Our high-quality products are crafted to handle a range of fibers, from fine materials like cashmere, silk, and merino to coarser fibers used in carpet yarns.

We employ various foundation types, each possessing unique characteristics suitable for specific counts and fibers:

Wool felt foundation with 3.00 – 4.50 mm felt and 4 – 5 – 7 or 9 plies of cotton. Because of its flexibility, wool felt has an excellent performance when used for fine counts.

Rubber felt foundation (also known as black cushion or OPCR) with 3.00 – 4.00 mm rubber felt and 5 – 7 or 9 plies of cotton. The rubber felt is used for its superior oil resistance and longevity.

Vulc rubber foundation with 1.00 mm vulc rubber and 3 – 4 – 6 – 7 or 9 plies of cotton. Vulc rubber has a superior opening capacity and can be used for a wide range of fibers.

We use high quality round and biconvex wires from European suppliers. Besides high-tensile bright wire we offer galvanized or stainless steel wire as well. Customization options include surface grinding, side grinding, polishing, and flame-treatment, based on customer preferences. The fillet width is determined by the roller diameter of the swift/cylinder, doffer, stripper, worker, or fancy.

Every roll of card clothing undergoes manual inspection in our factory, ensuring the highest reliability and longevity. Our wire has been successfully installed on machines such as Octir, Ramella, Kyowa, Tatham, Bonino, and HDB.

UB-Tec provides a variety of additional parts and consumables essential for spinning mills. Please click here to explore our comprehensive product lineup.

TYPES OF WIRE

The table below shows the different counts and the corresponding wire diameters. UB-Tec offers carding fillets with round or biconvex (oval) shaped wire. All wires are available in bright and galvanized steel. For fancy fillet we also offer stainless steel wire.

- English

- 36

- 35

- 34

- 33

- 32

- 31

- 30

- 29

- 28

- 27

- 26

- 25

- 24

- 23

- 22

- 21

- Continental

- 30

- 28

- 26

- 24

- 22

- 20

- 18

- 16

- 14

- 12

- 10

- 8

- 6

- 4

- 2

- 0

- Round (mm)

- 0.205

- 0.230

- 0.255

- 0.280

- 0.305

- 0.330

- 0.355

- 0.380

- 0.405

- 0.430

- 0.480

- 0.530

- 0.580

- 0.630

- 0.710

- 0.810

- Count

- 32/36

- 31/35

- 30/34

- 29/33

- 28/32

- 27/31

- 26/30

- 25/29

- 24/28

- 23/27

- 22/26

- 21/25

- 20/24

- 19/23

- 18/22

- 17/21

- Biconvex (mm)

- 0.305 – 0.205

- 0.305 – 0.205

- 0.355 – 0.255

- 0.380 – 0.280

- 0.405 – 0.305

- 0.430 – 0.330

- 0.480 – 0.355

- 0.530 – 0.380

- 0.580 – 0.405

- 0.630 – 0.430

- 0.710 – 0.480

- 0.810 – 0.530

- 0.910 – 0.580

- 1.015 – 0.630

- 1.215 – 0.710

- 1.420 – 0.810

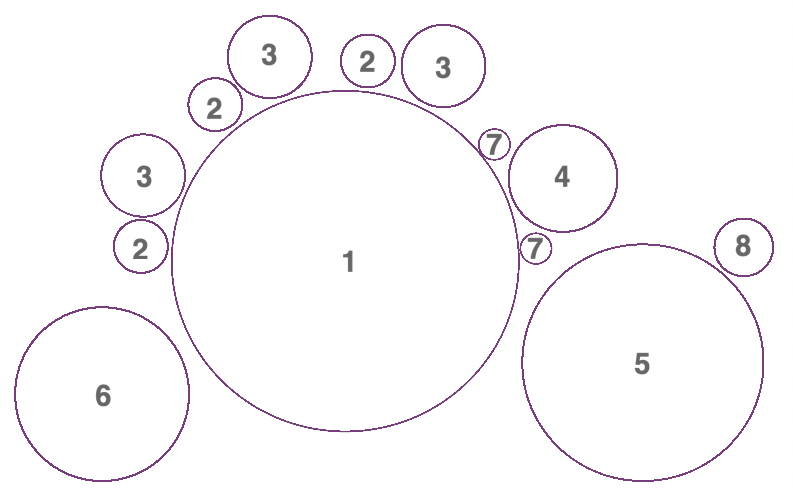

CARD CONFIGURATION

- Description

- 1 – Cylinder / Swift

- 2 – Stripper

- 3 – Worker

- 4 – Fancy

- 5 – Doffer

- 6 – Transfer

- 7 – Fly Stripper

- 8 – Doffer cleaner

- Typical width (mm / inch)

- 51 mm or 57 mm / 2″ or 2 1/4″

- 25,4 mm / 1″

- 38 mm / 1 1/2″

- 38 mm or 46 mm / 1 1/2″ or 1 4/5″

- 51 mm / 2″

- 38 mm / 1 1/2″

- 25,4 mm / 1″

- 38 mm / 1 1/2″